Indian railways which is the fourth largest railway network in the world by size, with 121,407 kilometres of total track over a 67,368-kilometre route and over 18million passengers and 2 million tons of freight traffic per day. On its rail network of 63,327 km, Indian Railways runs more than 200,000 wagons and 50,000 carriages pulled by more than 8,000 engines; it also runs 6,909 stations and has over 1,400,000 employees, which makes it the third biggest employer in the world.

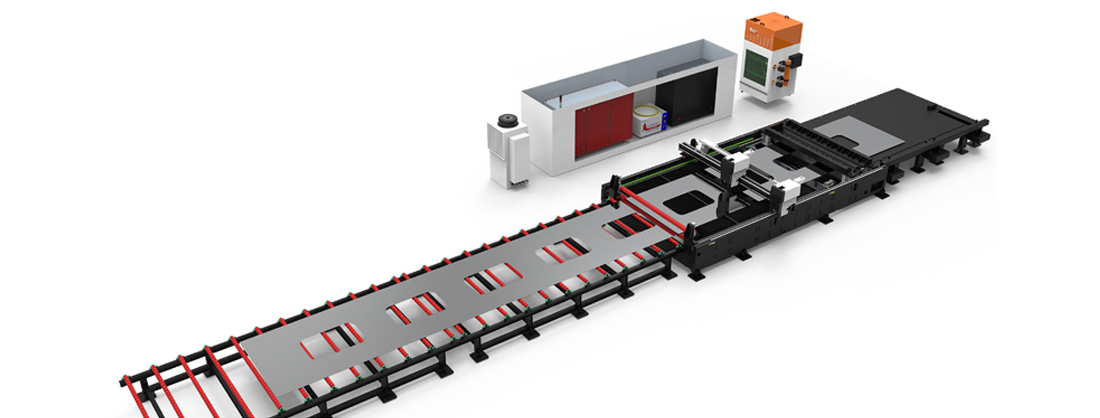

SIL recently commissioned an innovative SCW 2.5X25 automatic laser cutting and welding system to produce side walls and roofs for its passenger wagons. This is a sheet cut and weld system designed and customised by SIL as per client’s specifications. SCW stands for “Sheet Cut and Weld”, 2.5 indicates the maximum weld length,25m indicates the maximum welded sheet length that the system can be handle. The machine produces semi-finished parts which is used for manufacturing railway coach sidewalls and roofs including windows and doors of the coaches.

SCW 2.5X25 machine consist of Cutting and Welding base table with gantry and dual Z-axis of cutting and welding, Machine Enclosure, Control panel, Chiller, Fume Extractor, Raw Sheet Loading Table and finally Sheet rolling table. The sheets are rolled out automatically from trimming-welding station and cutting station with the help of two rollers at both station which will sandwich the sheet and move the sheets towards sheet rolling table. This operation is done be servo motors due which we can get the exact position of the sheet without any error.

| Laser Power | 3000/4000/6000W |

| Laser model | IPG |

| Welding area size | 2550mm |

| Laser cutting area Size | 4000 X 2500 mm |

| Y- Axis | 4050 mm |

| X-Axis | 2550 mm |

| Z Axis | 180 mm |

| Welding thickness | 1-3 mm Stainless Steel (3 kwatt ) Kindly contact for 6 kwatt |

| Cutting thickness | 0.5-25 mm MS/0.5-12 mm SS/0.5-8 mm Al |

| Positioning Accuracy | ≤ ± 0.1 mm/m |

| Max Welding Speed | 15 m/min |

| Max Cutting area rapid Speed | 80 m/min |

| Cutting Speed | 20 m/min |

| Cutting Acceleration | 0.5 G |

| Repositioning Accuracy | ≤± 0.05 mm |

| Resolution | 0.01 mm |

| Power | 380 V/ 50 HZ |

| 380 V / 60 HZ | |

| Weight without rolling table | 15 TON |

| Laser including 2 Fiber Cable & 2-way beam switch(Time Sharing) | |

| Advanced welding head with seam tracker | |

| Wobble Welding Head (Optional) |